|

| Classic Performance Products |

| Installing Tapered Wheel Bearings |

| By Rob Fortier |

|

|

I can remember the first time I disassembled the crank hub

on my Schwinn Stingray for no apparent reason other than because I could

and was introduced to caged ball bearings...or better yet, my garage

floor quickly becoming acquainted with numerous bearings rolling in every

direction! (I won't even get into

the intricacies of the New Departure rear hubs!) From then on, I gave more

respect to the reciprocating load-carrying devices each time I found myself

dealing with them. My '55 Stepside brought back fond memories of my experimental

youth, except this time around, I wanted to take advantage of a modem alternative-tapered

roller bearings. |

While ball bearings serve their purpose to effectively carry

loads and prevent friction, they don't take as kindly to today's modem road

conditions as tapered sealed bearings do. The newer style bearings can handle

much more side load, which is very critical, especially with radial tires,

and can deal with things like rain grooves, something that has proven detrimental

to ball bearings. With this in mind, many companies have produced conversion

kits to upgrade your front wheel bearings, and Classic Performance Products

offers one of the most convenient upgrades out there. |

Their newly designed kit consists of high-quality inner and

outer roller bearings, races, and rear seals. And for well under $200, it's

quite a deal for the benefits gained-better handling with longer wear life.

After rebuilding everything else in the frontend (see CLASSIC TRUCKS August

2001), it was very apparent that the wheel bearings had lived out their

lives on the '55. Follow along as I give new life to my

reciprocating rollers and install CPP's tapered bearing conversion kit.

You, too, may want to become a modem bearing convert! |

|

| The Classic Performance Products roller bearing conversion

kit consists of both inner and outer roller bearings and races, as well

as the rear dust/retainer seal. The axle nut and washer are also from CPP,

while the synthetic grease is Red Line's CV-2 high-performance extreme pressure

bearing grease-perfect for this job. (For more info on Red Line synthetic

oils and lubricants, call 707-745-6100.) |

|

|

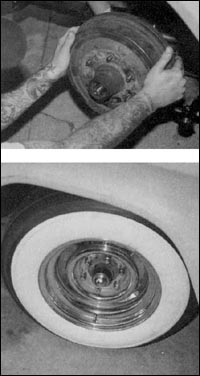

| After the drum and hub are removed as one (at which time the

front caged ball bearings and the inner race should fall loose), the rear

retainer seal needs to be pried out. I found that removing the felt ring

first allows the retainer to come out much easier. |

|

|

| A medium punch was used to (carefully) work the old races

out. In this case, each race came out with ease; others may experience more

difficulty removing them. Beneath the hub I placed a small piece of tubing

with an inner diameter large enough to allow the race to come out without

interference. |

|

|

| Once all the bearings and related parts were divorced from

the hubs, I found that somewhere along the line someone had swapped certain

bearings without changing the races, which could explain premature wear

and excess slop. The outer left-side bearings actually had a plastic cage

while all the others, varying in brands, were metal-caged. |

|

|

| The job remained easy from here on out. The races were lined

up in the hub, then started with a hammer by tapping around the perimeter

until about halfway in. The old races were used to finish driving them into

place. |

|

|

| Now the fun part, getting greasy! While II was offered the

use of a grease-packing tool, I prefer the old-fashioned way and getting

my hands dirty. Plus, the Red Line synthetic doesn't make as much of a mess,

but a roll of paper towels was kept nearby nevertheless. |

|

|

| With the rear bearings all lubed up and packed with even more

grease in the race, the rear retainer cover is carefully tapped in. CPP

recommends using Loctite 640 "green" sleeve retainer to provide

a secure adhesion of the seal. |

|

|

| The tapered bearings slid onto the spindle nice and snug like,

which told me I was in for a better ride as soon as I tightened-up the axle

nut, slipped a cotter pin in place, then knocked the dust cover on. I will

admit that I did experience quite a vibration after the initial road test,

but come to find out, all four of my "shiny" chrome wheels were

badly bent. Needless to say, the stock wheels were dug up, painted, and

put back into service. Now, I've got a smoother ride than I ever expected. |

|

|

|