Safely support vehicle at the finished ride height with the

desired front to rear rake at both the front and rear. Remove the existing

front suspension. Do not remove the front spring shackle mounts riveted

in the frame as they are used for a measuring location. You will also need

to modify the part of the frame rail that is turned up for the old steering

box mount so that portion is flat.

Boxing the front frame section is next using the supplied boxing plates.

The boxing plates should fit up against the radiator crossmember. You can

grind the inside edges of the frame rails flat so that the plates lay flat

against them, but you need to make sure you do not grind off too much and

make the rails too thin. The boxing plates can set on the lower flanges

of the rails in the front, but most of the flanges will eventually be trimmed

away for the rack C-notch and crossmember clearance. Fit the boxing Plates

to the frame rails, weld and grind smooth. |

|

|

|

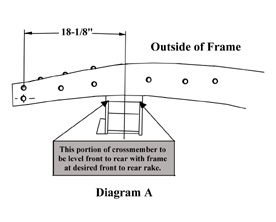

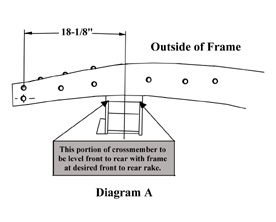

Measure back from the center of the front spring shackle hole

in the frame and make a vertical line as shown in Diagram A.

This will be the cantor of the crossmember and the spindle centerline. Slip

the crossmember up into the frame and center it on the centerline mark.

If it doesn't fit in the frame, grind the sides of the crossmember uprights

until you can got it into position. Make sure that the crossmember is all

the way up into the frame and seated against the underside of the frame

rail. Be sure top of flat portion of crossmember is mounted level front

to rear, with frame at desired front to rear rake. This is important for

proper alignment. You can tack the crossmember into place for now. |

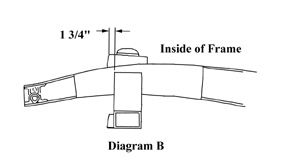

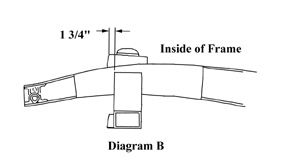

| Now you can install the shock towers. The shock towers sit

on top of the frame rails located 1 3/4" forward of the front of the

crossmember. See Diagram B. The taller part of the shock tower

is the front part and should be positioned toward the front of the vehicle.

Fit the shock towers fully against the side of the frame rails. You can

also grind them to fit against the tops of the rails. Now tack weld the

shock towers in place. |

|

|

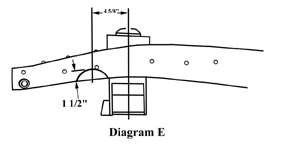

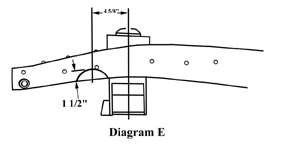

The C-notch for the rack is the last part to be done. Measure

forward 4 5/8" from the centerline and up 1 ½" and make

a mark. Now draw a 2 1/8" radius using your mark as the top of the

radius. See Diagram E. Cut out the material inside the radius

to form the notch leaving 1/8" of material inside the notch for precise

fitting. Try the fit of the C-notch plate. Finish grind the notch for a

good fit and correct location of the C-notch plate. Tack weld the plate

in place. Remove the rack after C- notching both sides of the frame. |

|

|

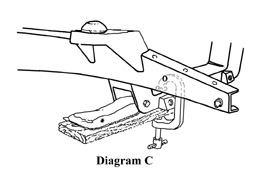

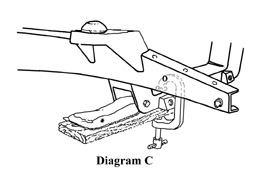

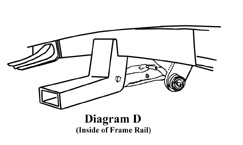

| We do not recommend using strut rods. Tubular control arms

distribute brake load much better. If you choose to use strut rods - use

the following instructions. The lower control arms and strut rods can be

used for locating the strut rod plates and gussets. Using a 2x4 and a C-clamp,

install the control arms as shown in Diagram C. Install the

strut rods onto the control arms. Assemble onto the strut rod ends the large

rubber bushings, including the cupped washers, and strut rod plates. Align

the tops of the plates with the underside of the frame rails, then fully

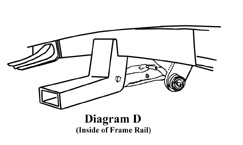

tighten the nuts on the strut rods to their fully seated position. See

Diagram D. The Pinto and Mustang strut rods are different lengths.

We recommend the Pinto strut rods, as they are shorter and will position

the strut rod plates more closely to the underside of the frame rails. The

Mustang strut rods can be used, however, by heating the rod at the bend

at the ball joint end and bending out enough to align the strut plates to

the bottom of the frame. The strut rods will act as alignment fixtures while

you tack weld the plates in place, then tack weld the gussets in place also.

See Diagram E. Now you can remove the strut rods and control arms. |

|

|

|

|

|

|

| Now you are finished with the crossmember assembly. Install

the rest of the front end. When the rest of the car is complete you can

use the following information to align your front suspension: |

|

|

| With vehicle weight and at ride height specifications are: |

| Camber: 0 degrees Caster: 1 - 1-1/2 degree positive, Toe in

1/16" for radial tires or 1/8" for bias ply tires. |

|

|

| Please note - It may take 100 or more miles of driving for

the springs to fully settle to ride height. They may settle 3/4" -

1" |