| Installation Instructions |

| |

PLEASE READ THESE INSTRUCTIONS THOROUGHLY BEFORE

BEGINNING INSTALLATION |

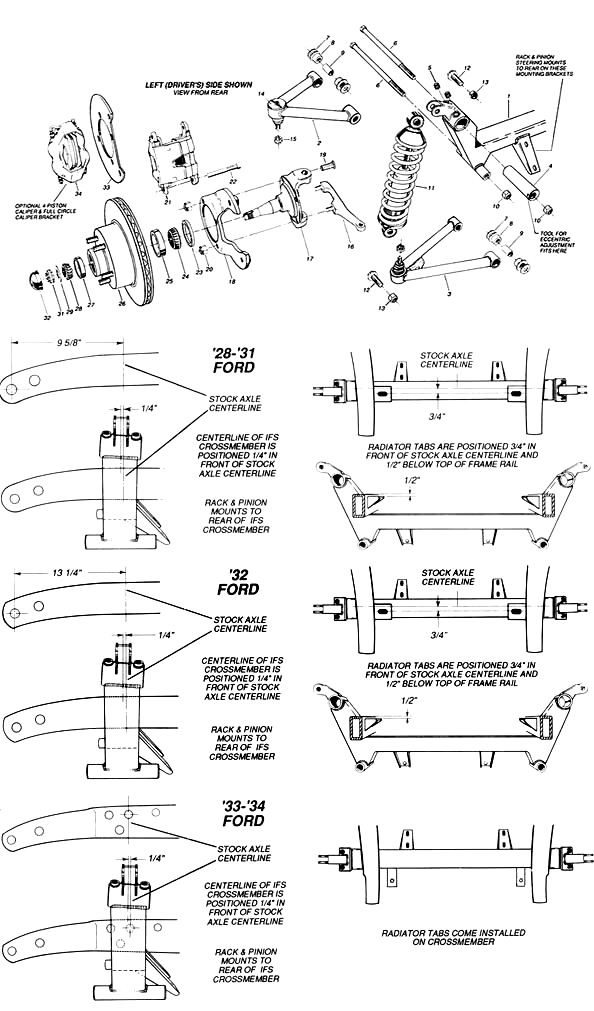

The installation of CPP's Independent front suspension

unit may appear complicated, but it is really very simple. Because CPP has

engineered all the correct angles and geometry into the crossmember itself,

all that's required are a few careful measurements to locate the crossmember

correctly on your chassis before welding it into position. If you are installing

the IFS unit onto a stock frame, there is some work involved in preparing

the frame for the installation, but the remainder of the job can be accomplished

with everyday hand tools. We recommend that all welding be performed by

a qualified welder. We also recommend that you have the alignment checked

at a front end shop when you are finished.

The installation procedure is the same for all '28 thru

'34 chassis, but the location measurements differ. Please be sure to use

the correct dimensions from the diagram for your particular car shown below. |

| |

|

| 1. |

PREPARING THE STOCK FRAME |

|

· Remove all of the old steering and suspension components. |

|

· Tack weld two braces to the top and bottom of the

frame rails behind the original crossmember to insure that frame rails do

not move. |

|

· Remove original crossmember by drilling out the rivets. |

|

· Box the frame rails and weld up the rivet holes left

by the original crossmember. |

|

· Finish grind all welds. |

| 2. |

INSTALLING THE IFS CROSSMEMBER & RADIATOR TABS |

|

· Mark stock axle centerline on the frame rails as

per diagram at right that applies to your chassis. |

|

· Fit IFS crossmember squarely on rails, top and bottom,

with the centerline of the crossmember located 1/4" forward of the

stock axle centerline. |

|

· Tack weld IFS crossmember to boxed frame rails. |

|

· Recheck all measurements. (Check measurements diagonally

to check for squareness) |

|

· Weld crossmember to rails on all sides. |

|

· Weld radiator tabs in position as per diagrams. |

| 3. |

INDEPENDENT SUSPENSION ASSEMBLY |

|

· Install Lower Control Arms onto crossmember. The

lower arms are identical, so there is not a left or right. |

|

· Install the Upper Control Arms with the Eccentric

onto the crossmember. The upper arms are marked right and left as they are

different. |

|

· Install the Spindle, Brake Rotor assembly (assembly

comes with bearings packed and seals installed) to the ball joints with

the caliper brackets and steering arms facing the rear. |

|

· Install the Rack & Pinion steering gear. |

|

· Install the Coil-over Shocks. |

| 4. |

SETTING RIDE HEIGHT |

|

· With full car weight on suspension, Lower Control

Arm pivot should be 1/2" to 1 " lower than the center of the Ball

joint sleeve. To adjust, jack up the car to remove the weight and then turn

the lower rings on the Coil-overs. The Lower Control Arms will angle slightly

uphill towards the wheels when properly set. |

| 5. |

SETTING CAMBER |

|

· Loosen set screw locks on Eccentric housing. |

|

· Rotate Eccentric by inserting the provided tool or

an equivalent 114" diameter object (phillips screwdriver) into the

hole on the side of the Eccentric. Rotating Eccentric is easier with car

jacked up, but Camber must be checked at ride height. |

|

· Camber should beset at 1/4" Positive. |

| 6. |

SETTING CASTER |

|

· With set screw locks still loose, Caster is set by

sliding Eccentric slightly fore or aft within it's housing. Gentle tapping

with a soft hammer may be required. |

|

· Set Caster between l" and 1-1/2" Positive,

making sure that both left and right sides are set the same. |

|

· Tighten set screws to lock in Caster and Camber settings. |

| 7. |

SETTING TOE-IN |

|

· Set Toe-in by adjusting the tie rod ends on the Rack

& Pinion steering gear. |

|

· Toe-in should be set at 1/32" for radial tires

and 1/16" to 1/8 " for bias-ply tires. |