Tie-Rod Upgrade Tie-Rod Upgrade

1932- 1959 Chevy/GMC Specific

Ball to Tapered Stud - General

MOST IMPORTANT

Safety is the single most important factor when undertaking

any modification project. Any changes should be carefully studied to see

how the modification will effect other components. The planed modification

itself must be looked at closely to see if it and the components used are

safe.

ORIGINAL EQUIPMENT

Originally, the early trucks from 1932

to 1959 used a tie rod end that cupped a ball trunions on the end of the

steering arms. These tie rod ends consist of five separate parts contained

in the housing. These parts are the seats, spring, safety plug and end plug.

The seat caps surround the ball trunions and are held in place by spring

tension exerted by screwing down on the end cap. As an assembly, the tie

rod sits atop the ball trunions on the end of the steering arm. A foam rubber

washer between the housing and the trunions base it used to seal water and

dirt out. A grease zerk in the house provides a means for lubrication. Originally, the early trucks from 1932

to 1959 used a tie rod end that cupped a ball trunions on the end of the

steering arms. These tie rod ends consist of five separate parts contained

in the housing. These parts are the seats, spring, safety plug and end plug.

The seat caps surround the ball trunions and are held in place by spring

tension exerted by screwing down on the end cap. As an assembly, the tie

rod sits atop the ball trunions on the end of the steering arm. A foam rubber

washer between the housing and the trunions base it used to seal water and

dirt out. A grease zerk in the house provides a means for lubrication.

A REAL PROBLEM

The real problem with the original

tie rod assembly is its strength and durability. The foam seal did not last

long, which allowed water and dirt to enter the housing causing rust. In

areas of the country where salts and chemicals are used to control ice and

snow, it only worsens the effect. Soon the spring would freeze or brake,

increasing the possibility of separation from the steering arm. Old grease,

which harden in the housing end, also fouled the spring causing the same

problem. Under hard braking and turning situations, the tie rod and steering

arms would separate causing catastrophic results. The real problem with the original

tie rod assembly is its strength and durability. The foam seal did not last

long, which allowed water and dirt to enter the housing causing rust. In

areas of the country where salts and chemicals are used to control ice and

snow, it only worsens the effect. Soon the spring would freeze or brake,

increasing the possibility of separation from the steering arm. Old grease,

which harden in the housing end, also fouled the spring causing the same

problem. Under hard braking and turning situations, the tie rod and steering

arms would separate causing catastrophic results.

Up until the mid ‘60’s

most trucks required chassis lubrication every 1000 miles or 4 months, which

ever came first. This type of lubrication requirement was sooner than a

regular oil change, so it wasn’t done on time in most cases. There

are 24 lub points on a stock 48-55 1st truck. If you are not doing your

own chassis lubrication, then I can almost bet you that not all your lub

points are getting their fair share of lubrication. The point is, the lack

of lubrication leads to the early failure of any tie rod and this tie rod

isn’t very tough to begin with.

REPLACMENT

The

original design tie rod, when in new condition, is pretty solid. There is

a little spring give in the connection to the steering arm, but acceptable.

Add some time, radial tires, a rough road and you get squirrely pulls and

lane floating. If you add disc brakes to the picture, you get a disaster

waiting to happen. This is why you would want to replace the old style OEM

tie rod end with the new OEM replacement ends. Sealed Power used to be the

largest manufacture of these replacement ends, they have since discontinued

production and are now manufactured by Golden State Pickup Parts. The

original design tie rod, when in new condition, is pretty solid. There is

a little spring give in the connection to the steering arm, but acceptable.

Add some time, radial tires, a rough road and you get squirrely pulls and

lane floating. If you add disc brakes to the picture, you get a disaster

waiting to happen. This is why you would want to replace the old style OEM

tie rod end with the new OEM replacement ends. Sealed Power used to be the

largest manufacture of these replacement ends, they have since discontinued

production and are now manufactured by Golden State Pickup Parts.

GETTING DIRTY

Anybody can do this job if

they have a hammer, screwdriver, adjustable wrench and a flat file. There

is no machine work in this project. If your real good (lucky) you may not

need to rest the toe-in. This project takes about 4 hours and is one of

the best upgrades you can do on the early trucks. Please remember, SAFETY

is the name of the game when modifying any OEM design configuration.

First things first, I plan

to leave out all the details of this project that are of the common sense

variety, like use wheel blocks, stand jacks, your head, ect…

Ok,

first, set the tires straight forward on the ground. Then measure from the

center of the ball trunnion on each of the steering arms. This measurement

will be needed to set the proper length of the drag link. Following this

method will usually prevent the need to reset toe-in. Sometimes you have

to remove the wheels and hub in order to loosen the steering arm bolts.

If this is the case, jack up the front end and scribe a center line on the

center tread of each front tire. Measure the distance between the tire centers

for a second reference. Ok,

first, set the tires straight forward on the ground. Then measure from the

center of the ball trunnion on each of the steering arms. This measurement

will be needed to set the proper length of the drag link. Following this

method will usually prevent the need to reset toe-in. Sometimes you have

to remove the wheels and hub in order to loosen the steering arm bolts.

If this is the case, jack up the front end and scribe a center line on the

center tread of each front tire. Measure the distance between the tire centers

for a second reference.

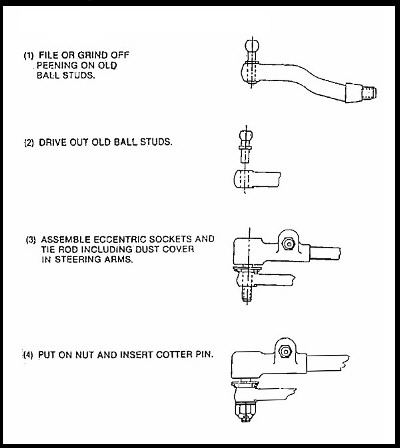

Next, remove both steering

arms and drag link as a unit. The driver side steering arm will need to

be separated from the steering link before removal. Remove the cotter pins

and unscrew the end caps on the old tie rod ends. Separate the tie rod ends

from the steering arm ball and remove the drag link Grind or file the swaging

off the bottom side of the ball trunnion. You have file off enough of the

swage when you can see a small circle appear on the casting boss. Drive

the trunnion out with a punch or old screwdriver. After the ball has been

removed, dress the other side of boss with a file. Clean, paint and reinstall

the steering arms.

Next,

remove the old tie rod ends from the drag link. Clean & paint the drag

link shaft. Wire brush the threaded ends to remove any paint. Center the

tapered stud on the new tie rod and thread them on the drag link. The stud

on the new tie rod ends will be the new center to center distance. The goal

is to replicate the same length of the old assembly. Once the original center

to center measure has been achieved, test the assembly in the new holes.

You should be real close. If the tires are still on ground do not force

the studs off center in an attempt to mount the drag link. Simply adjust

the tie rod ends in or out evenly until the assembly slips in easily. If

the wheels are off the ground, adjust the drag link in or out to achieve

the same center to center distance between tread centers. Install and tighten

the castle nuts on the new tie rod ends, don’t forget the cotter pins.

Tighten the tie rod ends collar clamp to secure them firmly on the drag

link shaft. Install the lubrication zerk and lub the tie rods. Test drive. Next,

remove the old tie rod ends from the drag link. Clean & paint the drag

link shaft. Wire brush the threaded ends to remove any paint. Center the

tapered stud on the new tie rod and thread them on the drag link. The stud

on the new tie rod ends will be the new center to center distance. The goal

is to replicate the same length of the old assembly. Once the original center

to center measure has been achieved, test the assembly in the new holes.

You should be real close. If the tires are still on ground do not force

the studs off center in an attempt to mount the drag link. Simply adjust

the tie rod ends in or out evenly until the assembly slips in easily. If

the wheels are off the ground, adjust the drag link in or out to achieve

the same center to center distance between tread centers. Install and tighten

the castle nuts on the new tie rod ends, don’t forget the cotter pins.

Tighten the tie rod ends collar clamp to secure them firmly on the drag

link shaft. Install the lubrication zerk and lub the tie rods. Test drive.

WRAP UP

After you have test driven

the vehicle you will have to decide whether it needs the toe-in reset. If

you feel that the toe-in needs to be reset, rotate the rear tires to the

front and test drive the vehicle again. If you still feel the toe is out,

I would refer you to the factory manual for setting the toe-in yourself.

If you feel you are not able accomplish this task yourself, then you should

try an alignment shop that understands older vehicles. There is not a lot

to setting the toe on these trucks. |

Tie-Rod Upgrade

Tie-Rod Upgrade