| Classic Performance Products |

| Engine Side Mounts and Cross Member Installation |

| Courtesy of Danchuk Manufacturing, Inc. |

|

| We would like to thank Danchuk Manufacturing, Inc. for providing

the following technical article and photos outlining the procedure for installing

side mounts and crossmember. The procedures are similar for any unit you

may be using and can be bolted in or welded. We are bolting them in as we

feel this is what most “do-it-yourselfers” would do. |

- You will need:

• Side Engine Conversion Brackets

• Side Engine Mounts

• Engine mounts and “L” brackets to support the rear crossmember

• Rear Crossmember

• Rear Transmission Mount

• Qty 4, 3/8” grade 5 bolts 1.25” long

• Qty 2, 3/8” grade 5 bolts 1” long

• Qty 4, 3/8” grade 5 bolts 5” long

- • Qty 8, 3/8” Lock Nuts

• Qty 16, 3/8” Flat washers

• Qty 2, 3/8” Lock washers

|

• Electric, Air or Cordless Drill

• 3/8” Drill Bit

• Level

• Tape Measure

• “C” Clamps

• Engine or Engine block

• Transmission or complete transmission case.

• Engine hoist or equivalent.

• Chain or engine strap.

• Mechanics Square or equivalent.

• Welder (if you plan to weld the mounts in place) |

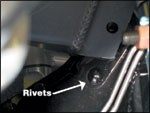

In this article we will cover a couple of ways to find the

correct position for the side mount conversion brackets. In Method One we

will mock up an engine and transmission in the frame and measure for a correct

fit. In Method Two we will show you how to use the original mounts to find

the mounting spot. Both ways are acceptable and will yield satisfactory

results but Method Two can only be used when using conversion brackets putting

the engine in the stock location.  To give you a preliminary frame of reference,

the side mount conversion brackets will install on the frame just behind

the rivet on the frame where the frame starts to curve in at the front.

This rivet basically attaches the front area of the frame to the main side

rails. To give you a preliminary frame of reference,

the side mount conversion brackets will install on the frame just behind

the rivet on the frame where the frame starts to curve in at the front.

This rivet basically attaches the front area of the frame to the main side

rails. |

The “L” brackets for the rear crossmember

will bolt or weld to the frame and the crossmember will sit on it and bolt

in place thus supporting the rear of the engine/transmission assembly. The “L” brackets for the rear crossmember

will bolt or weld to the frame and the crossmember will sit on it and bolt

in place thus supporting the rear of the engine/transmission assembly.

We will use an engine bolted to a transmission to get the

exact positioning; you can use just an engine block and transmission case

or one of the trick plastic engine blocks available if you have access to

one.  We do not recommend trying to simply measure

when installing these. Always mock up the engine and transmission in the

frame for best results. We do not recommend trying to simply measure

when installing these. Always mock up the engine and transmission in the

frame for best results. |

Method One

1. Install the engine side mounts on your engine or engine block and tighten. |

|

|

| 2. Install your rear transmission mount to the rear mounting

pad on the transmission. |

|

|

| 3. Hang the left and right side engine side mount conversion

brackets on the engine mounts. Do not tighten. |

|

|

| 4. Connect your engine (or mock up engine) and trans to a

hoist and lift the assembly into the approximate position above the frame.

Getting someone to help position the side mounts, slowly lower the assembly

until the mounts are in position at the rivets. The “L” bracket

on the side mount conversion kit may not fit flush on the frame. This is

okay. The mounts shown mount the engine in the stock location and are for

a seamless frame. If you are using the 3/4” forward mounts for an HEI

or big block, the installation procedure will be the same as described here. |

|

|

| 5. Next you will place a level across the valve covers. Level

the engine assembly in the frame. (Be sure your frame is sitting on a level

surface before you try and level the engine in the chassis.) Pull the engine

assembly forward in the chassis until the side mounts hit the front rivets.

This will give you the preliminary position in the frame for the side mount

conversion brackets and you can now drop the engine so the brackets contact

the side rails and are holding the engine in place but the assembly is still

being supported by the hoist. |

|

|

| 6. Take a floor jack and place it under the rear tail shaft

of the transmission for support. Jack it up so the engine and trans is sitting

approximately where it needs to be. We will measure precisely in step 9. |

|

|

| 7. With your tape measure, position the tail shaft so it is

centered between the frame rails. Now your front conversion brackets should

be in the correct position and you can lower your assembly further onto

the frame rails. Keep the assembly supported on the hoist until you are

completely done, however. We will not weld or drill holes for the side mount

conversion brackets at this time as we want to position and bolt in the

rear cross member before welding or bolting in the front mounts. |

|

|

Method Two

Method Two is very similar to Method One except you will install the original

mounts on the front of the motor and position the brackets where they fall

in lieu of “guesstimating” the position at the rivet.

Note: This method can only be used if you are installing

the kind of mounts that mount the engine in the stock position. Using this

method on the conversion brackets for HEI or big block will not position

the engine assembly in the proper position and allow clearance of the HEI

or big block valve covers at the firewall. HEI and big block brackets position

the engine/trans assembly 3/4” forward.

Once the original mounts are in place you will lower the engine assembly

into position on the original mounts and where the side conversion brackets

end up will be where you attach them to the frame. Leveling the motor and

centering the transmission between the frame rails is still necessary using

this method but it leaves no guesswork to the exact positioning of the engine

in the frame rails. As in Method One, we will not drill holes or weld the

mounts into place until the rear cross member is installed. Either Method

One or Two will yield satisfactory results but Method Two is easier and

requires less engineering. |

|

|

| Once you have the engine/trans assembly positioned in the

frame it is time to install the rear cross member. Once this is done the

position from front to back of the engine/trans assembly will be locked

in place. |

|

|

| 8. Position the rear cross member on the rear transmission

mount and bolt it in place on the rear transmission mount. |

|

|

| 9. Adjust the height of the floor jack so the transmission

crossmember ends are about 1” or so above the bottom of the frame at

the highest point. The brackets will probably be on an angle. Take the “L”

brackets and clamp them to the ends of the crossmember. The transmission

crossmember will sit on the “L” bracket when installed. Each crossmember

will sit at a different height depending on your frame and engine/trans

assembly. Generally, your engine should sit on a 1-2 degree back slope.

Whichever crossmember you are using, position it accordingly. |

|

|

| 10. Once you have the brackets in place on the crossmember

bring them out and rest the back of them on the frame. Measure from the

top of the frame to the top of the “L” bracket and be sure the

measurement is the same for each side. This is to be sure the trans is level

in the frame. Also double check that the tail shaft of the transmission

is still centered between the frame rails. Adjust the rear of the transmission

with the floor jack if necessary. Check the level at the valve covers to

be sure you are still square in the chassis and level. |

|

| 11. Once you are sure both sides are even and the assembly

is centered between the frame rails clamp the “L” bracket to the

frame to hold it in place. At this point if you are planning to weld the

“L” bracket to the frame you may do so. If you are planning to

bolt them in, carry on to the next step. |

|

|

|

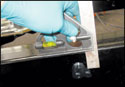

| 12. Mark where the holes on the ends of the crossmember are

on the “L” bracket and then mark some corresponding holes where

you want to drill to mount the “L” bracket to the frame. Remove

the clamps and the brackets and take the brackets to the bench. |

|

|

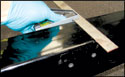

| 13. Drill the holes you marked in the “L” bracket.

Then bolt the “L” bracket to the crossmember. Mark the frame where

the holes on the “L” bracket are located making sure the engine/trans

assembly is still level and even between the frame rails. Then remove the

“L” bracket from the car. |

|

|

| 14. Drill the holes in the frame on the inside where the marks

from the “L” bracket are. Then, using a Mechanics Square measure

how far down from the top of the frame the holes are. Scribe a line on the

inside of the frame at each hole. Using your Square again place it on the

top of the frame and line the Square up with the line on the inside of the

frame. Scribe another line on the top of the frame. Then, line the Square

up with the line you scribed on the top of the frame and measure down from

the top the same amount as the dimension you had on the inside of the frame.

This is where you will drill the holes on the outside of the frame so your

bolt can come through to mount the “L” bracket. (If you are performing

this with the body on the frame make your measurements from the bottom of

the frame) |

|

|

| 15. Drill the holes for the bolts on the outside of the frame

and reinstall the “L” brackets. Be careful when you tighten the

bolts holding the “L” bracket to the frame. Remember that if you

get too carried away you could bend the sides of the frame in. You are using

lock nuts, so they only have to be tight. If you are not using locknuts,

Locktite or a similar thread locker can be used here. |

|

|

| 16. Now that the rear is secure you can turn your attention

to the side conversion brackets. Start by marking where the holes in the

brackets are on the frame. You should still be level and lined up properly. |

|

|

|

| 17. Remove the engine and trans assembly and drill out the

holes where you marked them on the frame. If you are welding the mounts

in place leave the engine in the car at least until you have tacked the

mounts in place. You can completely weld them with the engine installed

if you prefer. |

|

| 18. Bolt the mounts to the frame. You may find that the mounts

do not fit flat on the frame. This is okay and will not affect the strength

or effectiveness. If you are welding the mounts in place you can add a shim

if you like, but this is not necessary. If you are bolting them in place

you can place shims between the mount and the frame as well, but this is

not necessary. Follow the instructions for the mounts in regard to the number

of bolts needed and their position. |

|

| 19. Bolt the assembly back in the chassis if you removed it

and you are done. If you have done everything correctly, a level placed

on the valve covers will show plumb and the engine and transmission assembly

will be sitting evenly between the frame rails. (A slight variance will

not cause any problems.) |

|

Note: Some fluctuation in where these components are installed

in each individual frame is to be expected. We provided dimensions that

came from the seamless frame we were working on. All frames differ somewhat

from each other and the seamed frame differs substantially from the seamless

frame. The key is to remember that the rivet we spoke about in the very

beginning of this article represents the common starting point for the installation.

Also, big block installations will require some modification of the firewall

to allow the big block to fit.

We hope we took some of the mystery out of doing this installation

and conversion. It looks complicated, but if you go slowly and follow these

instructions you should be able to do the job in your garage with a minimum

of problems.

Now where did we put that 502 with the Richmond 6-speed? |

|

|

| It's always best to have shop and assembly manuals on hand

to make sure your installation is correct and to make the project as easy

as possible. We recommend factory manuals, available at Greg's

Automotive |

|

|

|