| Improved Rear Braking From Classic Performance

Products |

| Modern Disc Braking for Classic GM Trucks |

| By Mike Self |

|

|

|

|

| CPP's kit is available with or without emergency cable ready

calipers. |

|

| After driving around in our Suburban for a while, we had come

to the conclusion that the present brake situation just wasn't cutting it

anymore. The problem started with a pinhole leak in one of the rear flexible

brake lines (which quickly drained the rear portion of the master cylinder),

so after we fixed that problem we became a little worried about the condition

of the rest of the braking system. True, the truck had already been outfitted

with front disc brakes and a rear end out of a 78 Chevy, but thafs not really

saying much con- sidering that the newest parts were still close to a quarter-century

old! Once we got the brakes patched up at IF Customs, we decided that it

would be in the truck's best interest (and the best interest of anyone dri-

ving it) to replace the outdated parts with some quality aftermarket stuff. |

So, a call to Classic Performance Products in Buena Park,

California, confirmed that there was indeed a front and rear disc kit available

for the 78 components that were already installed on the Suburban, and best

of all the parts were bolt-on. The components are available plain, cross-drilled,

slotted, or cross-drilled and slotted. In a future issue, we'll be upgrading

the original front rotors with cross-drilled and slotted CPP units

(we already installed a set of CPP drop spindles when IF Customs 'bagged

the Suburban), and we will also swap out the rusty master cylinder and brake

booster with a 9-inch CPP combo. |

|

|

| The 78 rear end we had installed in the Suburban had drum

brakes that were a bit better than the originals, but they were still pretty

outdated. |

|

|

|

| Luckily for us, the drums came off with little effort. A firm

tug on each side had them off in no time, exposing the antiquated internals,

which looked like they had seen better days. |

|

|

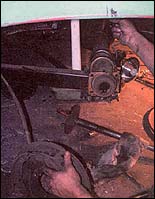

| Since the complete drum assemblies are to be removed, including

the backing plates, the brake lines are loosened up and removed. They are

then gently moved out of the way. You don't want to dam- age the hard lines,

as doing so will net you a trip to the auto parts store and some repair

work. |

|

|

| The rear end inspection cover is next to be unbolted, the

axle shaft retainers must be removed from the differential to allow the

axles to slide out. |

|

|

| Once the inspection cover is pried loose, the gear oil is

drained. |

|

|

| With the retaining clips removed, the axles should easily

slide out of the axle housing. |

|

|

|

| A quick way to remove the entire brake and bocking plate assem-

blies is to sim- ply unbolt the backing plates and disconnect the emergency

brake cables. Each unit will come off in one big piece. |

|

|

| After positioning the new CPP caliper mounting brackets, they

are bolted onto the axle housing flanges. |

|

|

| The brake calipers are now prepared for installation by attaching

the new flexible brake line extensions. |

|

|

| From here, installing the disc setup moved quickly. The axle

shafts are reinstalled, the new CPP rotors are slid on, and the calipers

are bolted on. |

|

|

| After attaching the new flexible brake lines to the hard line

and bleeding the brakes, the instal- lation is complete. After heating up

the brakes a few times, we noticed a considerable improvement in braking

and reduced pedal effort, equating into a much more confident driving experience. |

|

|

|