| Classic Performance Products |

| Installing a Master Cylinder and Power Brake

Assembly |

| By Jeff Tann |

|

|

| Whoa power is as important as go power in any street rod,

and today most street rods are equipped with disc brakes so they can slow

down just as quickly as the car in front of them. Safety should be a concern

to anyone building a street rod or street machine, and having excellent

brakes is not just a good idea but should be mandatory as well. This street

rod, a '35 Ford, will be equipped with Wilwood front disc brakes and Chevy

rear drum brakes, and a top-quality master cylinder with power assist was

required. |

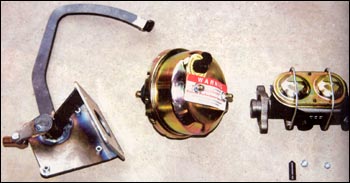

The owner decided to equip the '35 Ford chassis with a bolt-in

master cylinder and power booster kit from Classic Performance Products

(CPP). The master cylinder is a brand-new item cast by the company specifically

for street rods and street machines. One was ordered that works perfectly

with the disc/drum setup used on this car. If you are building a chassis,

this master cylinder, power booster and pedal kit is easy to install and

should take only a few hours to complete if you don't figure in the time

it takes to hook up the brake lines. |

The installation is easy, but you will need a metal-cutting

device, such as a 3-inch cutoff wheel or a plasma cutter. The rest of the

installation will require an electric drill and various hand tools. If you

are working on a '35-'40 Ford and plan to hook up a master cylinder, follow

along and we'll show you how easy it is. |

|

| 1) The brake pedal assembly comes with a template for the

installation. We cut out the template, punched the holes for the bolts and

located the proper position for the template on the framerail crossmember. |

|

|

| 2) The template was traced on the crossmember. We found that

three of the bolt holes line up to existing holes and only one will have

to be installed. |

|

|

| 3) The new hole in the crossmember was cut out with a plasma

cutter. This could also be done with a 3-inch cutoff wheel, but it wouldn't

be as precise and would be a slower process. |

|

|

| 4) A close look reveals the nice, clean cut that the plasma

cutter made. Only minor sanding will be required to get it perfect. Notice

that three of the bolt holes are already in the frame, but one will have

to be installed. |

|

|

| 5) Following the mark made on the frame, the bolt hole was

drilled with an electric drill motor and a small step drill. |

|

|

| 6) Using the kit's button-head Allen bolts, the brake bracket

was bolted on the crossmember. Here, they are installed finger-tight. |

|

|

| 7) After the bolts were installed, they were tightened with

an Allen wrench and a 1/2-inch open-end wrench. |

|

|

| 8) The vacuum booster was installed next and secured with

the nuts supplied in the kit. The booster looks great with the gold-cad

finish. |

|

|

| 9) The pedal shaft was installed through the boss in the bracket.

It's a good idea to lubricate the shaft before it is permanently installed. |

|

|

| 10) The female Heim joint end was installed on the booster

drive rod. |

|

|

| 11) The pedal was installed over the shaft assembly and then

the securing bolt was tightened with an Allen wrench and box-end wrench. |

|

|

| 12) The booster assembly was connected to the power booster

with the bolt and locknut supplied in the kit. |

|

|

| 13) The master cylinder was equipped with the small drive

fod that was supplied in the kit. Notice that it was lubricated before it

was installed. |

|

|

| 14) The master cylinder was installed on the two studs in

the power booster and then the 9/16-inch bolts were installed finger-tight. |

|

|

| 15) The bolts were secured with a large 9/16-inch box-end

wrench. The master cylinder cap is also gold-cad-plated, and together the

booster and master cylinder look terrific. If you look closely, you can

also see the black vacuum fitting in the booster. |

|

|

| 16) Here is the booster and master cylinder assembly mounted

in the '35 frame and ready to plumb. The assembly fits great and the pedal

assembly is in the same place as the original. |

|

|

|