|

| Classic Performance Products |

| 1971 Camaro Brake Upgrade |

| By Steven Rupp |

|

|

|

| Monster brakes are all the rage these days. Rotors big enough

to block out the sun mounted inside rims that look like they belong on a

covered wagon from the Old West are showing up on more and more hot rods.

But some gearheads actually like their 15 inch rollers, or don't have the

coin to blow on a set of dubs. This isn't to say they don't want their Camaros

to have killer braking; they just want to take a more reasonable approach

to getting it done. |

Thanks to Classic Performance Products (CPP), guys can now

have their cake and eat it, too. Killer-looking binders that will stop hard

and easily fit inside 15-inch hoops are just a day of wrenching away. To

see how easy or hard-these parts would go on, we decided to graft a set

onto a buddy's '71 Camaro. It's your typical project car, and the owner,

Jon Lindstrom, just bought a new set of shiny 15-inch wheels. |

The Camaro still wore its original brakes, and to say they

were ugly would be an affront to the word. Besides being cosmetically challenged,

they were also mechanically worn out. and the rear drums were starting to

act up. The drums would be updated to a disc brake arrangement, while the

fronts would be overhauled with a CPP direct replacement kit. |

|

| 1. The heart of any brake system is the calipers. CPP offers

brand new units in a variety of finishes. We opted for the powderpaint at

$50 a pair, but you can get them chromed as well. The fronts have the same

huge 2 15/16 inch piston as the factory units, and when combined with the

right master cylinder and good pads, they offer exceptional performance. |

|

|

| 2. While drum brakes do get the job done, they aren't the

best looking behind a sweet wheel. They also lag in perfonnance when compared

to modem disc brakes, especially after repeated hard stops. The rear disc

convernion kit from CPP ran $599, and we upgraded the caliper finish for

$50 and the rotorn for another $75. Everything needed for the conversion

was in the kit, including brake lines, e-brake cables, hardware, and gaskets

for 10- or 12-bolt differential covers. |

|

|

| 3. There's no way around it, if you want to ditch the drums,

then you need to pull the axles. We yanked the cover off the old U-bolt,

dropped the pin, and pulled the Clips. This allowed us to slide the axles

from the housing. |

|

|

| 4. With the axles removed, we took the easy route and just

severed the old e-brake cable with a cutoff wheel. Since the CPP kit came

with new rear e-brake cables, this was the fastest way to get the old junk

off. CPP provided new brake hard lines, so we removed the old ones as well. |

|

|

| 5. We then removed the four bolts that held the old drum assembly

to the axle flange and were rewarded with a clean slate to start installing

our new parts. We also took a moment to inspect the axle bearings for wear. |

|

|

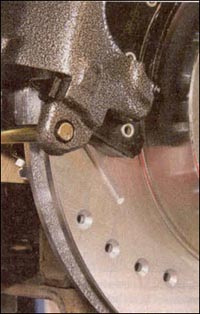

| 6. The first step in installing the new CPP brake system was

attaching the caliper bracket to the axle flange as shown. We made sure

to use the lock nuts provided in the kit. |

| |

|

| 7. Since the rotor hats are about 1/8 inch thicker than the

old drums, CPP supplied slightly longer 7/16 inch wheel studs. We used a

press to install these in the old axles, but we could have used a vise and

a hammer to get it done as well. |

|

|

| 8. With the new studs installed in the axles, were installed

them into the housing and then put on the sparkl ing zinc-washed rotors.

They are directional, so we were careful to put them on the correctside. |

|

|

| 9. With two old 7/16 inch nuts holding the rotor in place,

we then bolted the new caliper to the CPP bracket. CPP included shims in

case the caliper didn't line up with the rotor, but in our case it was dead

on. |

|

|

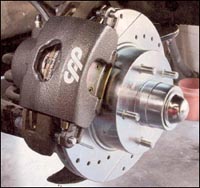

| 10. While the powdercoating and zinc washing did set us back

a few bucks, there's no denying how killer it looks. Best of all, the new

parts will keep looking great for a long time. The slots, like the venting,

help to cool the rotors as well as provide a space for heat and gas to escape,

thus improving braking performance. The slots help clean the area between

the pad and the rotor surface. The holes are mostly for looks, and the zinc

coating will keep rust out of the equation. |

|

|

| 11. With the caliper installed, we connected the new e-brake

cable and ran it back to the rest of the system. It was extremely hard to

get the Clip on to secure the cable to the caliper, but we got it done after

a flurry of curse words. On the otherside, we figured out that it was easier

to do with the caliper off the car. |

|

|

| 12. In an effort to make this install something you could

easily do in your driveway, CPP includes these cool little brackets for

the brake lines. By using the supplied band clamps, you don't have to do

any welding during the install. Sweet! |

|

|

| 13. With the rear system installed, we moved to the front

brakes, which still worked, but looked like hell. With lindstrom's new billet

wheels, the brakes ugliness was only accentuated. The fix for this was supereasy. |

|

|

| 14. We unbolted and removed the old caliper and then pulled

the battered rotor. The castlenut and washer would be reused, so we put

them in a safeplace. This was a good time to pull the old dust shield and

give it some fresh paint. We could have bought a replacement set from Cpp

for $49, but we opted to take the more wallet friendly route. |

|

|

| 15. After installing the new bearings and seal, we packed

the hub with grease and slid the rotor onto the spindle. Once in place,

we secured it with the original castlenut and washer. We were careful not

to overtighten the castlenut. It needs to be snug, but free spinning Lastly,

we dropped in the cotterpin and installed the new dustcap. |

|

|

| 16. The front calipers included brakepads, but we decided

to upgrade to CPP's cer amic pads, According to Jim Ries of CPP, We want

our systems to offer smooth quiet braking capabilities under a wide range

of temperature and road conditions. And we certainly don't want annoying

brake-generated noise during our drive. Anotller characteristic that makes

ceramic materials attractive is the absence of noticeable dust All brake

pads produce dust as tlley wear. The ingredients in ceramic compounds produce

a light-colored dust that is much less notice able and less likely to stick

to the wheels. Consequently, wheels and tires maintain a cleaner appearance

longer. |

|

|

| 17. The new front brakes look killer and will easily bring

the Camaro down from speed. Since the parts were designed to be a direct

replacement, the installation only took around 20 minutes per side. Costs

were $98 for the calipers, $95 for the rotors, and $39 for the new brakelines.

We upgraded the calipers with powder paint for $50, the rotors for $75,

and added ceramic brake pads for $39. Add it all up and we spent $39 for

these killer looking brakes. |

|

|

| 18. Technically, we could have gotten away with running the

same master cylinder, but the rear chamber's smaller fluid volume could

have caused us headaches down the line, According to Ries, The reason for

this is that disc brake calipers have much larger pistons than wheel cylinders,

so as. your brake pads wear, your fluid level drops dramatically If you

use a disc/drum master with the smaller rear chamber on a four-wheel disc

application, you run the risk of running the small reservoir side of the

disc/drum master cylinder dry before you wear out the brakepads, Not a safeway

to do a four-wheel disc conversion. The good news is that a replacement

wasn't expensive. |

|

|

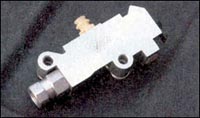

| 19. This 1 1/8-inch bore "large port" master cylinder

set us back $59, but the best part is that it's a direct replacement for

what was on the car. That meant we didn't need to hassle with cutting and

flaring brake lines. Upgrading the finish to match the calipers ran an additional

$30. They also offer chrome plating, or you can save the cash and just rattle-can

the master. |

|

|

| 20. Like the master cylinder, this combination valve is a

direct replacement for the OEM unit in the Camaro. As Ries explained, Many

people use names like proportioning valve, distribution block, metering

valve, and combination valve, but they are usually all talking about the

same part. This is a combination valve. Most of these valves look the same,

but are different depending on the application. A disc/drum would be different

than a disc/disc valve in function, but they look almost exactly the same.

Our disc/disc valve provides two pounds of residual pressure front and rear.

It also meets federal safety standards by including the pressure differential

switch. |

|

|

| 21. After bench bleeding the master, we installed it onto

the Camaro along with the new CPP proportioning block. The process was drama

free, and when we were done we were able to bleed the whole system and get

the Camaro back on the road. The total installation of the rear kit and

front parts took all day, with most of that time spent converting the rear

drums to disc. Now we just need to get the rest of the second gen looking

as good as the new brakes. |

|

|