|

| Classic Performance Products makes it easy

to steer your |

| 1972 Chevrolet C-10 - Simple C-10 Solutions

- Rearend Refresh |

| By Grant Peterson |

|

|

|

Why is it always the little things? They seem to be able

to make or break just about anything in life, from trucks, taxes, to the

opposite sex, but let's just stick to trucks here. Last month we showed

what it takes to rebuild a GM 12-bolt truck rearend, which is definitely

one of the bigger activities one could do when it comes to wrenching on

a truck. Along with this job there are a few small yet potentially difficult

tasks that need to be addressed, especially when you're reinstalling that

nice new rearend in your old truck/work in progress.

Father Time and Mother Nature are always two forces we

deal with when working on older vehicles, and more often than not neither

one has been too kind to the automobile. Simply removing the rearend from

our '72 Chevy C-10 should be relatively easy, but mix in many years spent

out in the elements and something simple can become quite frustrating, like

removing the well-rusted nuts on the U-bolts that hold the rearend to the

trailing arms. |

Some form of heat was definitely in order, and the cutoff

wheel was looking even better at one point. Even if you don't have to resort

to such brute methods of removal, there are still a handful of questions

that need to be answered, like how do you get the old hardware looking good

again? While you're under there, you notice the shocks' steep forward angle

since lowering your truck-how do you fix that? Say you want to put a diff

cover on that freshly rebuilt rearend that holds an extra quart of gear

oil, only to find that it hits the stock Panhard bar. In today's world,

where more old trucks are put on the road and expected to keep up with modern

vehicles versus restorations, these become real problems. |

Any one of these situations can be solved on its own depending

on your situation, or done all at once, which would be easier in the long

run. They all can be done at home in the garage or driveway if need be.

Read on for the answers to these questions and how to keep the little things

from becoming big problems, and how to get the most performance out of your

truck! |

|

| 1. Before getting too carried away, we measured from the frame

to the rearend Panhard bar mount for later reference to make sure the rearend

stayed centered after it was all said and done. Since the stock Panhard

bar's bushings were shot, it was easier to replace the whole bar with CPP's

adjustable Trac Bar. More on this in a bit. |

|

|

| 2. Since last month we followed the break-in procedure and

logged enough miles to necessitate a gear oil change in the rearend. Unfortunately,

the stock truck 12-bolt doesn't have a drain plug, so the easiest way to

drain it was to remove the differential cover. |

|

|

| 3. During the first attempt to use PML's cast-aluminum extra-capacity

diff cover, we ran into one problem that is easy to see here: the PML cover

is obviously much deeper and hangs farther off the back of the rearend and

hits the Panhard bar.... |

|

|

| 4. In a truck with parallel leaf springs and no Panhard bar,

this wouldn't be an issue, but on a lowered truck with trailing arms like

our '72, it's a major problem. |

|

|

| 5. We took our dilemma to the forward thinkers at CPP, and

through a bit of in-house R&D they came up with a solution. From the

top to the bottom: the stock piece; the CPP adjustable Trac Bar; and their

adaptation of their own 36-inch Deluxe Trac Bar that mounts in the same

location on the frame as the stock one, but uses a bracket that goes on

the passenger-side trailing arm. CPP's Deluxe Trac Bar is ideal for trucks

that have been lowered 4 inches or more in the rear, because it lessens

the rearend's side to side movement when the suspension travels compared

to the stock Panhard bar, plus they bent this one to clear the PML cover

so we can kill two birds with one stone. |

|

|

| 6. With the old diff cover off and the gasket surface cleaned

up, use a good-quality RTV gasket sealant and apply a bead to the cover

that passes on the inside of the bolt holes like so. |

|

|

| 7. After installing a new gasket and the new bolts provided

by PML, tighten and torque them down in a criss-cross pattern to 15 ft-lb. |

|

|

| 8. Next, the CPP Deluxe Trac Bar bracket goes on the passenger-side

trailing arm. The lower shock mount needs to be removed, and the U-bolt

needs to be raised up enough to slip the top of the Deluxe Trac Bar bracket

between the rearend and the trailing arm. |

|

|

| 9. The Deluxe Trac Bar kit includes a spacer for the driver's

side to raise the left side of the rearend up the thickness of the Trac

Bar bracket on the right, and is installed the same way. |

|

|

| 10. More than likely, if your truck has its original rearend

in it, your U-bolts will look like the stock ones on the right that were

more than a struggle to remove. Not only can the nuts be difficult to remove,

but once you do get them off, about 4 inches of the U-bolts pass through

the trailing arms, and after all these years of trapping dirt and water,

they have nicely rusted to one another. You can see how the originals taper

in now where all the rust has been chipped off. Well, CPP has just the cure

in both stock and extended replacement U-bolts like the ones on the left. |

|

|

| 11. As mentioned before, the Deluxe Trac Bar mounts in the

stock bracket on the bottom of the driver-side framerail, while the right

side now mounts on the trailing arm. In a stock diff cover situation, the

Deluxe Trac Bar would be straight, but CPP put the right bends in this one

that clears the PML cover. |

|

|

| 12. From below, we can see there is ample clearance between

the deep PML cover and the Trac Bar. Notice the handy drain plug in the

diff cover. |

|

|

| 13. To help finish off the rearend refresh once and for all,

we also picked up CPP's rear shock relocation kit. When you lower the rear

of the '67-72 Chevys, the rear shock angle become too steep, and this kit

helps correct it. |

|

|

| 14. The trickiest part of installing the shock relocation

kit is removing the stock upper shock mounts, which are riveted to a crossmember.

Use a drill, air chisel, or whatever your preferred method is, but just

be careful. |

|

|

| 15. The new upper mounts bolt into the stock rivet holes and

come complete with hardware. Just be sure to install the bolt next to the

shock from the bottom or the bolt will hang down and prevent the shock from

going into place. |

|

|

| 16. The CPP lower shock mounts do the same as the top, but

in the opposite direction. They move the bottom of the shock forward another

inch or so. |

|

|

| 17. The new upper mounts bolt into the stock rivet holes and

come complete with hardware. Just be sure to install the bolt next to the

shock from the bottom or the bolt will hang down and prevent the shock from

going into place. |

|

|

| 18. Because all these related pieces needed to come apart

to install the Deluxe Trac Bar kit, it makes it a perfect time to install

the new U-bolts and rear shock relocation kit. The lower shock mounts go

in the stock location under the trailing arms, with the shocks facing forward. |

|

|

| 19. Last month, Unitrax changed the ring-and-pinion ratio

in the 12-bolt from a 3.73:1 to a 3.42:1 with parts from Randy's Ring &

Pinion during its rebuild. This meant the speedometer had to be recalibrated

since it was reading 10-15 mph slow. This seemed like it would be a fairly

easy thing to accomplish since all that needs to be replaced is the speedometer

drive gear in the transmission that's easily accessible. Well, I soon found

out the local transmission shops won't sell parts, and trying to tell the

kid at the big auto parts chain store that I have a '72 C-10 with a 4L60

tranny in it and I just need a speedo gear was futile. Then the light went

on-we got the transmission from Gear Star; we'll call them. We told them

the tranny, rearend ratio, and rear tire size, and that we had a 42-tooth

speedo gear in there now, and they figured out that we needed to swap it

out for one with 37 teeth. |

|

|

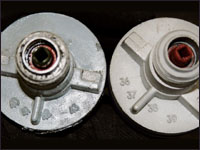

| 20. Along with the new 37-tooth speedo drive gear, Gear Star

also had the housing to match. There are numbers on the outside of each

housing that show which gears they can be used for, and it's important to

make sure they correspond properly. The one on the left came out of our

tranny and is good for 43-40 tooth gears, while the new one handles 39-36

tooth gears. |

|

|