|

| Classic Performance Products |

| 1955 Chevy Truck Dropped Axle Kit |

| By Grant Peterson |

|

|

|

It's been more than a few years, shall we say, since the

old trucks we love rolled off the showroom floor, and many have lived their

lives and passed on, been resurrected, or just managed to survive the scrapper

to live another year. Over the course of time, many trucks were "upgraded"

to suit the owner's work/driving needs, restored, or maybe customized, but

regardless which scenario, things like these were usually done on the cheap

to get by or to work within the owner's budget.

There will always be the debate about I-beam axles versus

IFS clips, and the biggest argument for or against the issue is cost. The

second factor is "how low do you wanna go?" and it's quite well-known

that an IFS will net the best ground-hugging results. But what if you still

can't afford to, or you can't bring yourself to cut up your stock frame?

I-beam axle trucks that have taken a more custom turn have seen their fair

share of botched lowering jobs over the years, with most ranging from dreadful

to dangerous, but to do it "right" and safely, you need to start

over with parts made to do the job. Flipping the axle on top of the springs,

removing leaves, and making spacers will only get you a treacherous, rough,

frame-on-axle ride with the potential of breaking important parts-possibly

causing an accident-not to mention bumpsteer and bad steering geometry. |

We knew someone with such a precarious frontend setup on

his '55 Chevy truck. It's an in-the-works custom inspired by the '50s Barris-built

Kopper Kart with a lowering job that could have dated back to those very

days. Besides the fact that the front suspension setup in the truck was

a bit dodgy, to say the least, there was no axle travel, which is pointless

and hazardous, so we consulted with the folks at Classic Performance Products

(CPP) in Anaheim, California, about the issue. They said they had the parts

to do the job right and end up with a decent ride in the end while keeping

the 'beam axle setup.

CPP offers a new 3-inch dropped axle, 3-inch dropped monoleaf

springs, new shackles complete with bushings and pins, U-bolts, short bumpstops,

shock mounts, shocks, and a beefy 1-inch replacement tie-rod bar to cure

your '55-59 Chevy suspension woes. All or part of this list can be used

depending on your needs or desires, but one thing is for sure, you won't

be able to get your non-IFS truck much lower than this and retain any sort

of decent ride without cutting the frame and opening up another can of worms. |

Of course, doing any amount of major lowering is a give-and-take

process, but one of the most important issues when it's all said and done

with these trucks is the drag link angle. The drag link connects the pitman

arm on the steering box to the steering arm on the spindle, and when there

is too much of an angle in the drag link, you get bumpsteer. To rectify

the situation after a dropped axle and/or leaves have been installed, the

steering arm needs to be heated with a torch and bent, usually down, to

level out the drag link. Obviously, this needs to be done right, or you

could not only hurt yourself, but could do something like set your truck

on fire and ruin parts, so ask for help or hire a pro when it comes time

for this portion. Everything else with this job is pretty straightforward.

So if you're tired of losing fillings while driving down the road or just

want to lower your stock truck, give CPP a call today and get down! |

|

| This custom '55 Chevy truck is the long-term project of a

local upholsterer and was inspired by the Barris Kopper Kart. Unfortunately,

it was lowered the way it might have been done back in the 1950s, which

doesn't cut it today. Using a new dropped axle and monoleaves from Classic

Performance Products (CPP), we're going to show you how to lower a truck

with an axle-the right way! |

|

|

| While there is the chance that nothing would ever happen with

a lowering job like this, there is always "what if." The leaf

packs had many leaves removed, the axle was flipped to the top of the leaf

packs, and hollow spacers in conjunction with long U-bolts left this '55-59

Chevy truck sitting in the weeds. With the weight of the truck at ride height,

the frame was resting on the axle! |

|

|

| With the truck in the air, the wheels, brake drums, and backing

plates need to be removed so we can get to the spindles. If you are keeping

your stock brakes, take care to retain all their parts; CPP has disc brake

upgrade kits for your truck-stay tuned for a six-lug disc upgrade on this

truck. |

|

|

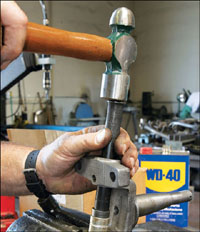

| Before trying to beat out the kingpin, make sure the tapered

cross-pin is removed. Once you have the spindles off, give them a thorough

cleaning and set them aside for later. |

|

|

| The remainder of the front suspension can come off as a unit

by disassembling the shackles at the end of each leaf spring. Make sure

to support everything before removal since this stuff is heavy. |

|

|

| With the frontend stripped from the Chevy, now would be a

good time to degrease the rest of the frame and clean up what might be hard

to get at later. Even though this truck is slated to be a wild '50s-style

custom, the same rules apply to a stocker. |

|

|

| CPP can provide all these parts as a kit or individual pieces

depending on your lowering needs. Here is their 3-inch dropped axle, 3-inch

dropped monoleaves, new shackles (including bushings), bumpstops, kingpin

kit, shock mounts, shocks, and last but not least, a beefy tie-rod bar and

tie-rod ends. |

|

|

| With the rear of one of the monoleaves in place, install the

special rear shackle bolt from the outside in. A bit of grease on new parts

will help things slide into place. |

|

|

| Install these threaded pins in the front eyes of the monoleaf. |

|

|

| Depending on the state of repair-or disrepair-of your truck,

you might have a tough time replacing the front shackle bushings that go

through the frame. The dimples on the outside of the new pins help keep

the bushing from spinning once driven into place. |

|

|

| After drilling a hole in the center of the frame where the

OE axle bumpstop would contact, this new shorty bumpstop from CPP can be

installed. In a situation like this where every inch counts, these short

stops do just the trick. |

|

|

| The CPP dropped axle can now be held in place and cinched

down using the new U-bolts. Make sure to install the lower shock mounts

on the front side of the axle. |

|

|

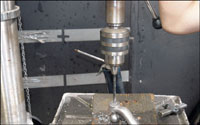

| Now comes rebuilding the spindles. The old kingpin bushings

need to be carefully driven out and the new ones installed. If you don't

have the tools or would rather not mess with this, most automotive machine

shops should be able to handle it. |

|

|

| Now that the spindles are as good as new, place them on the

dropped axle and hold it by inserting a greased kingpin. Next, the lower

bearing can be greased and installed between the bottom of the axle and

the spindle. |

|

|

| After handling the previous step, check the gap between the

axle and spindle by trying to slide in one or more of the provided shims.

If you need shims, pull out the kingpin and install them before replacing

the kingpin. Any remaining play in this area will lead to oblong kingpin

bores in the axle, which is bad. |

|

|

| Once everything is up to snuff, drive in the tapered cross-pin.

This keeps the kingpin in place. Don't forget to install and grease the

new grease zerks. |

|

|

| Shock mounts take lots of abuse over the years, and the stock

upper mounts on this truck were nonexistent. Luckily, CPP has new ones to

fill the void. After this, the new shocks can be installed. |

|

|

| Like many old trucks, these have an integrated ball on the

lower steering arms for old-style, screw-in tie-rod ends like the one on

top. Unfortunately, the stock tie-rod bars are also kind of wimpy by today's

standards and have been subject to reinforcements like the one on this '55.

CPP realized this long ago and makes these beefy tie-rod bars that taper

from the original thread size to 1 inch in diameter, and use either a stock

or modern tapered tie-rod end like the one shown, which we'll be installing. |

|

|

| The tie-rod/steering ball needs to be removed from the lower

steering arms to convert them to a modern tie-rod end. Flip the steering

arm over and start by carefully grinding the backside of the arm where the

ball end is. |

|

|

| Next, drill through the center from the backside so the ball

can be driven out with a big punch. This will leave the factory hole where

the ball end was installed and make it possible to insert the tapered end

of the new tie-rod in its place. |

|

|

| OK, let's look at one of the biggest issues you must deal

with when lowering a truck with a solid axle-drag link angle. The drag link

is the piece that connects your pitman arm on the steering box to the upper

steering arm on the left spindle. Look behind the spindle in this picture

and you can see that the drag link is at a drastic up angle from back to

front. There is also a binding angle where the front end of the drag link

goes into the upper steering arm. All of this misalignment is the major

cause of bumpsteer, which can be annoying, if not downright dangerous. |

|

|

| The heat wrench is the answer here. This is not for the faint

of heart, but must be done if you want to avoid the perils of bumpsteer

and premature failure of steering components. Before bending any part of

the steering arm, it must be heated cherry red all the way through with

a rosebud torch. Use a large, adjustable wrench to do the bending chores,

which should be done slowly. Remember, safety first! You can seriously burn

yourself doing this, or start a fire! |

|

|

| We can see the first bend at the right, which brings the upper

steering arm-and consequently the drag link-down, closer to being level.

The arm needs to be bent again near the drag link to flatten out the end

where the drag link goes, which will eliminate that misalignment we saw

earlier. |

|

|

| The lower you go, the more work needs to be done. The drag

link needed a little bend to the left to clear the axle when turning all

the way left; this was done in a hydraulic press, and done slowly so it

wasn't overbent. |

|

|

| After the steering arm has completely air-cooled-never use

water or compressed air-the drag link is put back in and is quite level,

which is just what we wanted! You may have to go back and regrease the kingpin

since that much heat can melt the fresh grease. Also, notice the shock has

been installed. |

|

|

| Now the new tie-rod bar can be put in place. This can be done

from either the top or the bottom, depending on what works best to clear

other suspension or engine components. We're pretty sure this new one won't

need any angle iron reinforcements like the old one ... |

|

|

| Well, there you have it-an old-school lowering job done right!

So those of you diehards who aren't ready to take the IFS plunge, call CPP

to get set up closer to the ground without cutting up your frame. If you

are using your stock/existing brakes, go ahead and reinstall them and get

back on the road. For this truck, we're going to finish with a six-lug disc

brake kit from CPP next month-stay tuned! |

|

|