Classic Performance Products

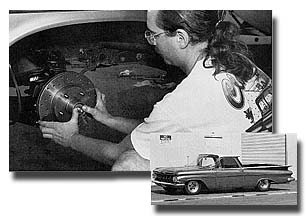

Drops and Stops a Classic El

Camino

|

| Part 1 Lowering the front end and installing disc

brakes. |

While there are many companies out there that supply

trick suspension hardware for enthusiasts of mid-fifties Fords and Chevys,

you might think that the classic El Camino owner has been forgotten. Wrong!

Classic Performance Products of Buena Park, California, can give the Elky

owner that down-in-the-dumps feeling and the reliable stopping power of

disc brakes with their two-inch lowered spindle and disc brake combination

kit. In addition, Classic Performance Products has the brake booster/master

cylinder to match.

|

For those who feel their Elkys could benefit from new

bushings, ball joints and tie rod ends, Classic also carries urethane bushings

that fit the stock sway bar Installing this hardware is the same for most

Chevy trucks. The fact that the control arms and cross shafts are designed

to fit one way is not unique, but it is best to note how they are constructed

before you disassemble them (a Polaroid camera works well), because this

will aid with re-assembly later. In part one, we will follow along as the

crew at Classic Performance disassembles

|

the front end and installs the new bushings and ball

joints, the drop spindle/disc brakes and the new coil

springs. Next month we will get into the disassembly of the rearend and

the installation of the tailing arm bushings, drop springs and Panhard

bar. With that done, the final step will be installing the booster/master

cylinder and brake line kit. These kits, whether used together or individually,

are a must for the classic El Camino owner, especially those who want the

added safety factor provided by the disc brake kit.

|

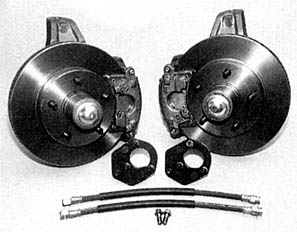

The disc brake/drop spindle kit for Classic Performance

comes with adapters and brake lines.

All the bushings, ball joints and tie rod ends come straight

from the Classic Performance catalog.

Classic also carries the urethane bushings for the stock

sway bar.

|

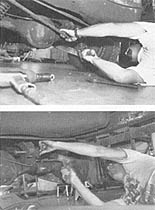

With the truck sitting securely on jack stands, the shocks

and brake lines have been disconnected and removed. The tie rod ends have

also been disconnected.

A floor jack has been placed under the lower arm and

raised enough so there is slight pressure on the spring. The nuts on the

ball joints are loosened to the last few threads but not removed.

|

The lower nut is removed and the floor jack is lowered

just enough to remove the spindle from the lower ball

joint. Do not lower the floor jack too much at this point, or you might

eat the spring. Remove the upper nut and then the spindle. The only piece

that will be re-used is the steering arm, which is bolted to the spindle. It will be removed, cleaned and inspected before

going back on the new drop spindles.

With the jack lowered slightly to take pressure off the

spring, a few sharp blows to the spindle are usually all that is required

to separate the spindle from the ball joints.

|

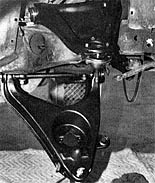

With the spindle removed, gently lower the floor jack

and remove the spring.

There

is a definite "front and back" and "side to side" when

it comes to the upper and lower arms on the El Camino, so note the location

prior to removing them. Better yet, take a Polaroid of the setup before

you disassemble it.

An air chisel is used to remove

the pressed-in bushings, but the old fashioned hammer and chisel will also

work. These shells are not going to be re-used, so it is not necessary

to be too careful with them. However, be careful not to damage the cross

shaft.

|

|

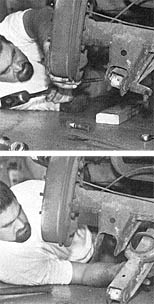

If

the ball joints on the upper arm are riveted in place, it means they are

stock. The chisel is used to remove the heads, and a grinder and a punch

will drive out the rest of the rivet.

The process of stripping the

lower arm is the same as that for the upper, except that the ball joint

is bolted in. Once the arms are stripped, they will be sandblasted and

checked for cracks or other damage before being painted and readied for

the new parts.

|

|

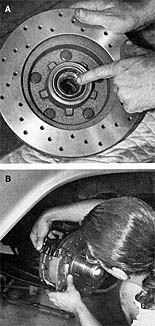

Installing the new bushings is fairly straight-forward.

(A) They are first disassembled, and then the shells are heavily greased.

(8) They are then driven in with a bushing attachment on the air hammer.

A socket and hammer will work, but the shell has to be completely seated

in the arm.

The

insert is made of a poly graphite, so it must be greased with the supplied

silicone-based lubricant. It is inserted into the shell along with the

inner sleeve.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

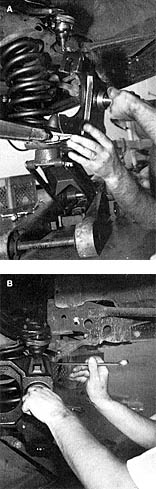

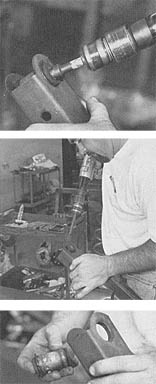

When installing the cross shaft in the lower control

arm, be sure it is facing the correct way. There is definitely a right

and wrong way to install it. The cross shaft has a flat side that

must be installed against the frame; the two mounting holes

go to the front.

(A) The ball joint is installed with two side bolts and

a nut on the main shaft. (B) One of the bolts acts

as a steering stop, and it goes to the rear of the arm. A new polyurethane

bump stop replaced the old rubber unit, so it was necessary to drill an

additional hole in the arm.

|

Now to the upper control arm. The cross shaft and bushings

have already been installed, so the next step is to install the upper ball

joint adapter. (A) The stock holes are drilled

out and (B) the adapter is bolted in place. (C) The

adapter is necessary to properly align the caster.

|

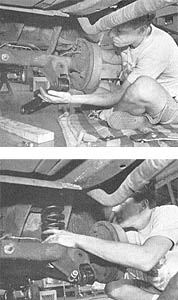

With that, it is simply a matter of bolting the arms

back up to the truck.

It is necessary to collapse the coil spring using a spring

compressor tool before you can install it.

The spring is set in place and the arm is raised slightly

using the floor jack. The spring tool is removed through the shock hole.

|

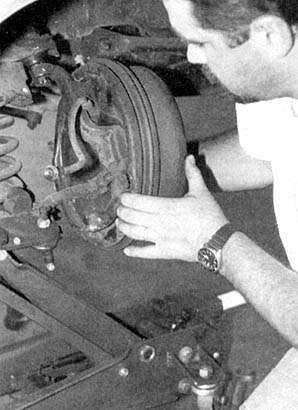

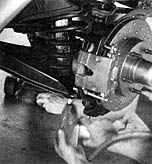

The spindle is placed on the lower ball joint, and the

nut is threaded onto the first few threads. (A) The

floor jack is then raised, the top of the spindle is set in place, and

the nut is applied. (B) The nuts are then tightened down.

The stock steering arm, which has been cleaned and inspected,

is bolted onto the spindle.

|

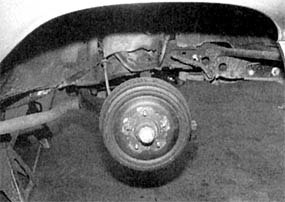

With the spindle in place, (A) the wheel bearings in

the rotor are greased up, (B) and the rotor and caliper

are installed on the spindle.

The adjustable Doetsch Tech shocks are set on the firmest

setting and then installed.

|

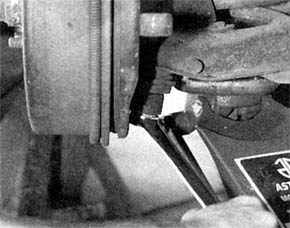

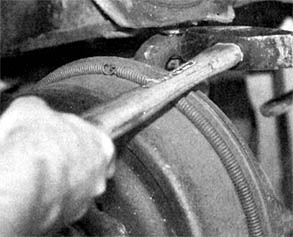

Now is the time to fully grease the ball joints and tie

rod ends.

New tie rods are also part of this rebuild/upgrade

and are bolted in place.

Because the Chevy had a stock sway bar, the old rubber

bushings were replaced with new urethane bushings.

|

Part 2 Lowering the rear end |

Part two will concentrate on refurbishing the rear suspension

and installing one of Classic's adjustable Panhard bars, as well as their

lowered springs, new bushings and a set of Doetsch Tech shocks. And last

but certainly not least, the addition of the front disc brakes required

that a new power assisted master cylinder be added. The stock unit

was a single reservoir design that had a hard time with the stock drums,

let alone the new discs.

|

Classic also carries pre-bent stainless steel brake

lines for a variety of vehicles, so naturally a kit was installed too. While there are not as many pieces to remove and replace as with

the front end, disassembling the back half of this project possesses a

few quirks of its own. For instance, the rear suspension on the '59 Elky

is a 3-link configuration. A what, you ask? You've heard of 4-link, and

trailing arms such as on later Chevy trucks, but what is a 3-link?

|

Well, this suspension consists of short trailing arms,

and a single upper arm that is connected to the right of the pumpkin, and

runs to a frame mount lust below the bed. The Chevy also came stock with

a non-adiustable Panhard bar (which was bent), so the rearend was hooked

up, it's just a little different than the usual.

Classic Performance Products has a complete line of parts for your classic

Elky, so for more information on these or other products that Classic Perfor-

mance sells, give them a call at (800) 522-5004 or (714)

522-2000.

|

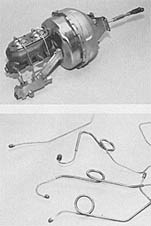

Classic offers this power booster/master cylinder that

is designed to work with the front disc brakes installed in part 1 above.

Also available are stainless steel brake lines that are pre bent and ready

to install.

With the truck securely up on jack stands, the dismantling

began. The Panhard bar is removed and the upper link will be next. The

floor jack was used to take pressure off, but a punch was still needed

to remove the bolts.

By gently lowering the jack, the springs are easily removed.

|

The lower shock mount also acts

as the lower trailing arm mount. Again, a punch may be needed to dislodge the assembly.

In their infinite wisdom, Chevrolet

decided to use two styles of bushings on the trailing

arms. One style is the standard shell type, and the

other is vulcanized to the arm. The

shell type is removed in the same fashion

as the front a-arm bushings were: drive out the center sleeve

and use an air chisel to drive out the shell.

|

The vulcanized type is a little more difficult to remove.

A welder's torch is used to heat the rubber bushing,

which can then be pushed out with a screwdriver. One

thing to be aware of is the odd fact that when the

torch is heating the rubber, the metal inner sleeve will launch out of

the bushing with surprising force, so be careful with your legs and feet.

This is also a job to be done outside, or your garage will smell really

bad.

|

After that it is simply a matter of re-assembling the

components. The use of Loctite is recommended.

|

A pair of adjustable Doetsch Tech shocks

are set on their firmest setting and then installed.

|

When installing the Panhard bar, careful measurements

are taken to ensure the rearend is centered. The bushings are also well

greased.

|

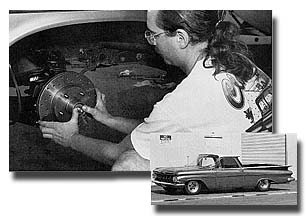

Classic Performance installed this new power booster/master

cylinder that comes complete with the correct valveing

mated to the demands of the new disc brake system. Vacuum

was taken from the center carb. This is not an option as the stock single

chamber master cylinder was barely able to stop the truck

when it had drum brakes, but will have no chance with the new front discs

in place.

|

The completed job.

|

xxxxxxxxxxxxxxxxxxxxxxxx |

|

| Classic Performance Products 378 E Orangethorpe

Ave., Placentia CA 92870 Tech Line 714-522-2000 |

|

TECH

| BOOKS | SUSPENSION

| BRAKES | STEERING | CONTACT

US | HOT PRODUCTS |

|

| © Classic Performance Products. This "website"

and all contents are property of Classic Performance Products.

Prices subject to change without notice. Not responsible for

errors or omissions. Please note that kits & prices

may vary between certain applications. |

|

|

|

|

|

|

|