Power Steering Fluid

Most power steering unit suppliers will recommend the use of fluid that

the vehicle manufacturer recommends. What

do you do on a specialty vehicle with a GM pump and a Ford rack? Classic

Performance Products recommends the purchase of power steering fluid supplied

by a high quality oil company. The label will state if it is compatible

with Ford/ GM/Chrysler, etc. Most systems require 2-3 quarts of fluid.

New vs Used vs Rebuilt

Purchasing used is gambling, especially when you don't know the history

of the source vehicle. When you connect a power steering pump to a rack

or gear, you are instantly contaminating one with the other. The fluid can

flow 8 to 10 quarts a minute and at that volume, it doesn't take long for

the contaminated fluid from one unit to infect the other. So, now your choices

are new or rebuilt. In many cases, new is no longer available and in some

case a new unit may never have been tested. The advantage of a Classic Performance

Products unit is that most of the older units are still available and CPP

test every unit that we sell. CPP can also custom build a unit to your requirement.

Noise Through the Column

Unless a vibration dampener or isolator is used

in the column shafting, you can expect to hear a hissing noise traveling

up through the column. Sometimes this can be quite irritating, so we recommend

you plan ahead an incorporate one into your shafting/U-joint measurements.

Speaking of the Column

As a reminder, when designing your column make

certain the input shaft or the rack or gear is taking no forces except rotational.

Any downward, upward or side forces will cause erratic steering and premature

failure of the unit.

Fasteners

All bolt and nut fasteners are important attaching parts in that they can

affect the performance of vital components. If replacement of these fasteners

becomes necessary, style, type, quality and grade MUST be equivalent to

OEM. DO NOT use a lesser substitute. Torque values must be maintained during

assembly to assure proper retention of vital

components.

Pressure Reduction

It is commonly thought that a GM/Saginaw style pump will not mate well with

a Ford rack. In fact Ford uses Saginaw pumps on some rack & pinion equipped

vehicles. Most all passenger car steering systems utilize pressure between

1000 and 1200 PSI. Classic Performance Products recommends the following

procedures when building your specialty vehicle:

1. Initially, utilize stock pressures on the power steering

pump.

2 Caster setting should be between 4-6 degrees positive.

3. After a few test drives, reduce pump pressure ONLY when the vehicle has

too much power steering assist at a parallel park situation.

Lowering pump pressure reduces assist at all speeds and

power steering is needed most at low speeds. The high positive caster setting

will tend to tone down the effects of power steering at high speeds and

will give the vehicle good returnability from a turn. A pressure reduction

kit can be purchased from Classic Performance Products that will reduce

pressure on all FM style pumps.

Remote Reservoir Set-ups

When using the small GM/Saginaw pump with a remote reservoir, we recommend

locating the reservoir as close to directly overhead the pump as possible.

An example of too far away would be locating the reservoir at the firewall

when the pump is near the front of the motor. The feed hose connecting the

two should be a minimum of 5/8 hose firm wall and if an AN style fitting

is to be used on the pump intake it must be a #10 and no less. These pumps

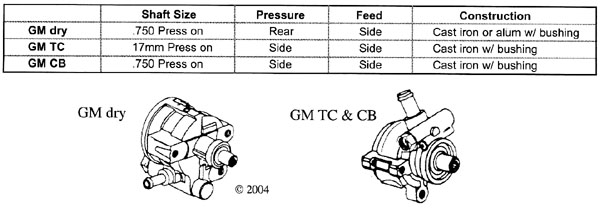

can mount in any position with the shaft facing forward. There are three

styles of this pump.

Getting It Up

Building a street rod or other specialty vehicle requires a different set-up

procedure than just replacing a worn out unit. Power steering systems are

self bleeding, but we must help them a little along the way. It is preferred

that the power steering system be the last engine. After everything is working

fine and all your adjustments are complete, now is the time to hook up the

power steering pump belt.

V-Belt System

1. Fill the steering system with your high quality fluid and let it set

undisturbed for a few minutes while you recheck your work. Leave the reservoir

cap off. Use this time to wipe the components off in preparation for leak

check and visually inspect the hose routing, belt alignment and attaching

hardware.

2. After your inspection, raise the front wheels off the

found and support the vehicle. Without starting the engine slowly begin

to cycle the steering wheel. The key here is "slowly"; about 1

revolution per 8-10 seconds. Continue to top off the fluid level at the

reservoir. When the level remains steady, inspect for leaks and start the

engine.

3. Check the fluid level and inspect for leaks. Some vane

type pumps require 1000 RPM or more to take the fluid down. Slowly cycle

the steering wheel in both directions, lightly contacting the wheel stops.

Continue to check the fluid level and add if necessary. If the pump begins

to get noisy, turn the engine off and let the system set for 15 minutes.

Air in the system will cause the pump to growl and the fluid level may rise

when the engine is turned off.

4. Repeat the above steps until the system is operating

normally. If air is still a problem after several rest periods, it may be

that air is entering the system faster than it can be expelled at the reservoir

fill. Look for leaks. Even the smallest of fluid leaks can be a source of

massive amounts of air entering the system.

5. Always test drive the vehicle, making sure it is safe.

Serpentine Systems

Obviously, the serpentine system does not allow for engine startup prior

to power steering startup. Therefore, follow all of the above steps and

take special precaution on step #2.

Six Easy Steps to Ordering a Steering System

1. Determine whether you will need a two or three U-joint

system. This is dictated by the angle, we recommend a 15 degree angle for

the optimum system, however up to 30 degrees is acceptable. If using a three

U-joint system, a support bearing is necessary. The center U-joint will

either be 3/4"00 x 3/4"00 or 3/4"00-36 x 3/4"00-36,

depending on whether you are using splined or DD shafts.

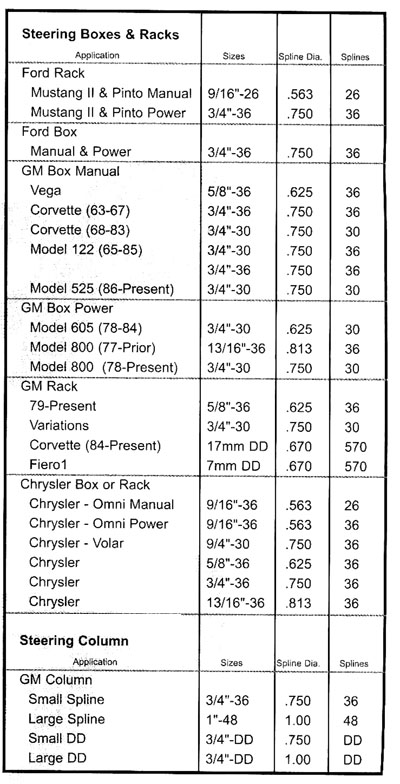

2. Use the Application Guide to select the rack and pinion

or box spline size you require. If the chart does not list your application,

just measure the diameter of the shaft and count the number of splines.

If there is a flat, count half the splines and double that.

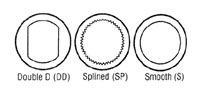

3. Measure your column (two rounds, two flats), measure

the round-it will either be 1"DD or 3/4" DD. If splined, measure

the diameter and count the splines i.e. 1"-48 or 3/4"-36.

4. To determine shaft length on a two U-joint system, measure

the distance between the rack and pinion or box shaft and the column, then

subtract 3.25 inches.

5. If using a three-joint system, we recommend using dowel

rods to mock up the system. Just measure the length of the dowel rod and

this will be the length of your shaft. Of course, you will need to order

U-joints prior to shafts.

Important Notes:

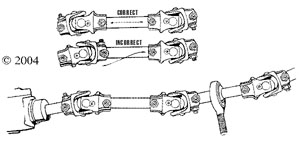

Phasing - Keep the forks of the yokes closest to each other In line and

center of the shaft to avoid binding.

Set screws are supplied on all Splined and "Double

0" U-joints. However, it is necessary to indent (by drilling) the shaft

to properly secure the set-screw mechanism. Loc-Tite should also be used.

The shaft should be flush with the ends of the U-joint

yoke - too short could sacrifice strength and too long will cause the shaft

to interfere with the operation of the U-joint. |

|

| To determine the spline size of a component (rack and pinion,

steering column and steering box), measure the outside diameter and count

the number of splines. If there is a flat spot on the shaft and some of

the splines are missing, count halfway around where there are splines and

double that number. We need to know how many teeth are in a theroretical

full circle. |

|

Available U-joint Combinations are:

A) Smooth Bore on both ends

B) Smooth Bore and Spline or Double D

C) Spline and/or: Double D on each end. |

|

|

Common Fitting Sizes

Because there is no clear rule of thumb, we list

below some of the more common power steering fitting sizes. There are many

others not listed and if you have questions about them, please call.

|

Pressure |

Return |

| GM Metric Pump |

16mm (M16-1.5) O-ring |

Push / Clamp |

| GM SAE |

3/8 tube size (5/8-18 inv. fl.) |

Push/Clamp |

| GM R&P |

18mm (M18-1.5) O-ring |

16mm (M16-1.5) O-ring |

| GM Metric Gear |

18mm (M18-1.5) O-ring |

16mm (M16-1.5) O-ring |

| GM SAE Gear |

7/16 tube size (11/16-18 inv. fI.) |

3/8 tube size (5/8-18 inv. fl.) |

| Ford Must II R&P 1974 thru 7-5-77 |

5/16 tube size (1/2-20 inv. fI.) |

3/8 tube size (5/8-18 inv. fl.) |

| Ford Must II R&P 7-6-77 thru 1978 |

5/16 tube size (1/2-20 iny. fI.) |

3/8 tube size (5/8-18) O-ring |

| Ford T -Bird thru 1988 |

5/16 tube size (9/16-18 inv. fl.) |

3/8 tube size (5/8-18) O-ring |

Although we encourage the CPPcustomer to use inverted flare

fittings, there are other methods of sealing off hoses. In any case, avoid

the use of pipe or thread dope or Teflon tape. These products can get into

the hydraulic system and do substantial damage.

Torque settings:

Inverted flare fittings should be torqued to 25-24

foot pounds

A-ring beaded hoses should be torqued to 20 foot pounds

Teflon ringed hoses should be torqued to 14-20 foot pounds

Other common torque settings:

Mustang R&P to cross member: 80-100 foot pounds

Ford R&P to cross member: 41-54 foot pounds

Gear to frame mounting bolts: 60-65 foot pounds

Pitman arm to sector retaing nut: 235-250 foot pounds

Pump keyway style pulley: 60 foot pounds |

|

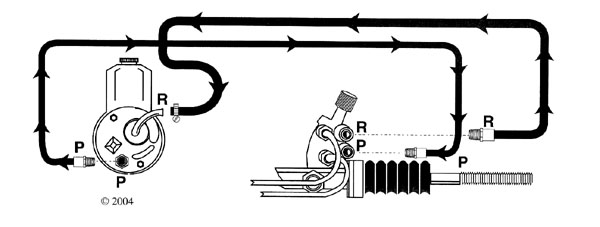

Rack & Pinion Pump Diagram:

|